What is polyethylene foam sheet? | Complete introduction to polyethylene foam board

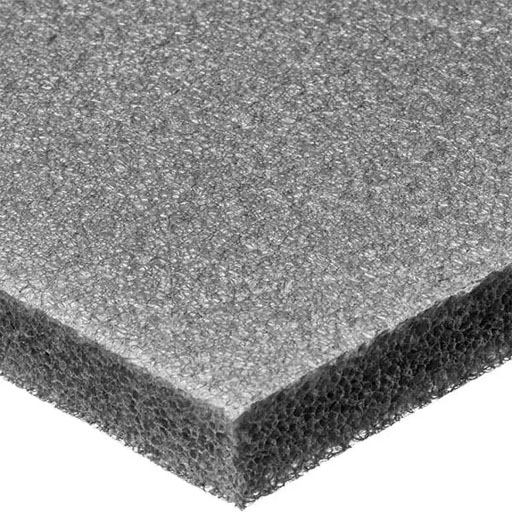

Sheet polyethylene foam, also known as board polyethylene foam, is a combination of polyethylene and air bubbles. Polyethylene was first made in England during the polymerization process of ethylene gas, and then after combining with air and trapping air bubbles inside, polyethylene foam was created.

The combination of air bubbles in polyethylene creates a very high cell tracking property. This feature has made polyethylene foam one of the best insulation materials, so that this product has wide applications in industry, construction and sports clubs.

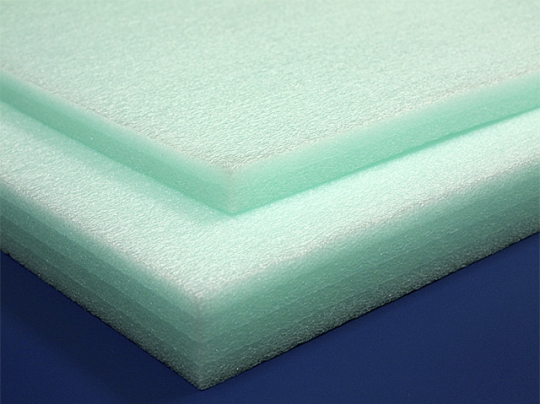

Polyethylene foam has different types such as sheet, roll, tube, crossling, metallized and adhesive polyethylene foam. Since the flexibility of this material is high, it can be designed and produced in any way.

Characteristics of laminated polyethylene foam

This product, which is also called polyfoam, is soft and highly flexible. In this way, it does not break easily against environmental pressures and can be used in curved places. There are no toxic or illegal substances in its structure, and it does not release any substance even during work, and it is considered one of the safe compounds.

Laminated polyethylene foam is heat, cold, electricity, moisture, water and dust insulating. Therefore, it can be used in wet or wet environments without any problems. To use these products in hot environments, be careful that they can withstand temperatures ranging from -30 degrees to +90 degrees Celsius.

The important point regarding the operation of this foam in hot environments is that they do not come into direct contact with fire. Also, polyethylene foam is resistant to corrosive substances and dilute acids and will prevent them from penetrating the surfaces. Polyfoam also has a high resistance against insects, so that insects cannot cause holes in it.

One of the other features of polyethylene sheet foam is its sound insulation. In fact, it is considered one of the best sound insulators and can largely prevent the transmission of various sounds and vibrations. Also, it is very easy to install polyfoam in the desired place, and due to its very low weight, its transportation is easy and hassle-free.

Application of polyethylene foam sheet

The unique features of this product have made many different industries prefer to use it. Because these foams are of better quality compared to other existing materials and are considered economical. Polyfoam has wide applications in the following cases:

- Backpack production

- Insulation of electrical appliances

- Insulation of ventilation channels

- Production of sports flooring

- Making different bumpers

- Insulation of water pipes of tanks

- Production of sports and medical mats

- Packaging industry as a shock absorber

- Making a helmet as an inner layer

- Making decorative items and home decoration

- Insulating the floors of houses to prevent the transfer of cold

- Sealing doors and windows of offices and residential buildings

- Automotive industry for inside doors, behind lights, dashboard and car roof

Also, polyfoams are used in amusement parks, heat insulation for refrigerators, parquet substructure, production of wrestling and gymnastics mats.

The price of sheet polyethylene foam and checking its other characteristics

This foam has a very low density so that its weight is equal to 25 kg per cubic meter. It can be produced in different colors such as white, black, green and red. This category of polyfoams are usually produced in sheets with dimensions of 2 meters long and 1 meter wide and different thicknesses (1, 2, 3, 4, 5, 6, 8, 10 to 30 mm) so that users can choose the best according to their needs. They choose the item.

Polyethylene sheets can be easily cut with simple razors if needed. They have a very long shelf life and are completely fiber-free. Therefore, unlike glass wool, they do not produce any fine dust. The price of polyethylene foam sheet depends on various factors.

In what industries is polyethylene foam sheet used?

Polyethylene Foam Sheet is used in many industries and applications. This type of foam is known for its insulating and light properties, resistant to water, impact and heat, ability to absorb pressure, vibration and sound, and high flexibility. Below, I mention some industries that use polyethylene foam sheets:

- Packaging and transportation: Polyethylene sheet foam is used as a suitable material for packaging and protecting products during transportation. This foam is used to make boxes, pallets, protective films and packaging for electronic products, glass, carpets and other items.

- Construction: Laminated polyethylene foam plays an important role in the construction industry. It is used for insulation in heating and cooling systems, sound insulation, manufacturing of door and window blades, insulation of pipes and piping systems, anti-shock and anti-moisture of building structures and use in flooring and underfoot insulation.

- Automotive industry: In the automotive industry, polyethylene sheet foam is used as an insulation material, absorbing vibration and sound and protecting against impact. This foam is used in making interior covers, seat foam, roof foam and columns.

What are the advantages of polyethylene sheet foam compared to other foams?

Laminated polyethylene foam has unique advantages over other foams. Below are some of these benefits:

- Lightness and flexibility: polyethylene foam sheet is very light and flexible. This feature makes it suitable for use in packing and transporting products. Also, it is possible to adjust and shape the foam in different thicknesses and dimensions.

- Insulation: Laminated polyethylene foam has very good insulation properties. This foam can insulate heat, sound and vibration. These features make it suitable for use in buildings, automotive and electronic industries.

- Resistance to water and moisture: Polyethylene foam sheet is very resistant to water and moisture. This feature makes it suitable for use in humid environments as well as packaging products that require protection against moisture.

- Impact resistance: Polyethylene sheet foam has high impact resistance. This feature makes it suitable for use in the packaging of impact-sensitive products, automotive parts manufacturing, and buildings that require impact protection.

Polyethylene sheet foam has high impact resistance.

What points should be considered in the production of polyethylene foam sheets?

Some important points should be considered. Below, I mention some of these points:

- Selection of raw materials: It is very important to choose quality and appropriate raw materials. Polyethylene with suitable density is used to produce foam. Choosing the type of polyethylene (eg LDPE, HDPE) is essential depending on the properties and purposes of the foam.

- Production Process: Production process: The production process of polyethylene foam sheets includes heating and melting polyethylene, adding a foaming agent to it, and then producing foam sheets. Adjusting the parameters related to temperature, pressure and time in this process has a great impact on the quality and final properties of the foam.

- Thickness and dimensions: For the production of sheet polyethylene foam, the thickness and specific dimensions of the sheets are considered. These dimensions should be set uniformly and according to the needs of customers.

- Quality Control: In every stage of production, quality control is very important. You must make sure that the polyethylene foam has the required density, resistance, insulation and other properties. Careful inspection and quality tests can help ensure the final quality of the foam.

- Environment: In the production of sheet polyethylene foam, attention should be paid to issues related to environmental protection.

What points should be considered when buying polyethylene foam sheet?

Some important points can be considered when buying polyethylene foam sheets. Below, I mention some of these points:

- Polyethylene type: Polyethylene foam sheets are available in different types such as LDPE (low density polyethylene) and HDPE (high density polyethylene). Each type of polyethylene has different properties and uses. Therefore, you should choose the right type of polyethylene based on your needs.

- Properties and characteristics: It is very important to check the properties and characteristics of polyethylene foam sheet before buying. This includes density, thickness, impact resistance, heat and sound insulation, water and moisture resistance and other properties. You need to make sure that the features of the foam match your needs.

- Dimensions and thickness: It is also important to check the available dimensions and thickness for foam sheets. It depends on your intended use. Make sure the dimensions and thickness of the foam match the needs of your project or application.

- Quality and standards: It is very important that the polyethylene foam sheet conforms to the quality standards. Checking quality marks and certificates can help ensure the quality of the product.

What are the similar items of this product?

Products similar to polyethylene sheet foam are:

- Polystyrene foam (EPS): This type of foam is also made of cellular plastic, but it is made of polystyrene. Polystyrene foam is used for insulation, packaging, manufacturing of industrial parts and construction.

- Polyurethane foam (PU): Polyurethane foam is a cellular foam produced from polyurethane. This foam provides good thermal insulation, sound insulation and impact resistance. It is used for various industries including automobile manufacturing, furniture and building insulation.

- Polyolefin foam (PE): Polyolefin foam is produced from polyolefins such as polyethylene and propylene. This foam is used for insulation, packaging and automotive industries.

- Polycarbonate foam (PC): This type of foam is made of polycarbonate and has high transparency and mechanical resistance properties. Polycarbonate foam is suitable for use in packaging, electronic insulation and construction industries.

Note that each of these foams have different properties and uses, and depending on the needs and use, one of them may be the best choice.

Factors such as the quality of raw materials, dimensions and size of polyethylene foam, whether it is covered or not, and market fluctuations affect the price of polyfoams. Hobab Sahel production group produces all kinds of polyethylene foams in various sizes and designs and covers all the needs of its users in this field.

This group has been able to gain valuable experience by working in this field for many years. Our experience, along with modern knowledge and the use of advanced devices and high-quality raw materials, have made us able to offer high-quality products.