Cellophane

Product categories

- 120 width bubble nylon 2

- 20mil polyethylene foam 1

- 3mm ethylene foam 1

- 4cm large ethylene foam 1

- 8mm large ethylene foam 1

- Bubble nylon (shock absorber) 13

- bubble nylon refrigerator 12

- bubble shock absorber nylon 12

- Bulk cellophane packaging 1

- bulk color bubble nylon 12

- Bulk polyethylene foam board 3

- Bulk polyethylene foam roll 13

- Bulk polyethylene foam sheet 3

- Cellophane 3

- Double foam mattress 4

- double layer bubble nylon 12

- Foam 2 major mills 1

- Foam mattress 5 cm 4

- Major 5 mm ethylene foam 1

- Major 6 mm ethylene foam 1

- Major foam mattress 3

- Major sofa mattress foam 4

- Medical mattress foam 4

- metric bubble nylon 12

- Polyethylene foam 18

- three layer bubble nylon 13

- two meter wide bubble nylon 2

- فوم تشک یک نفره 4

Based on thickness

BASED ON WEIGHT

- 20 kg 1

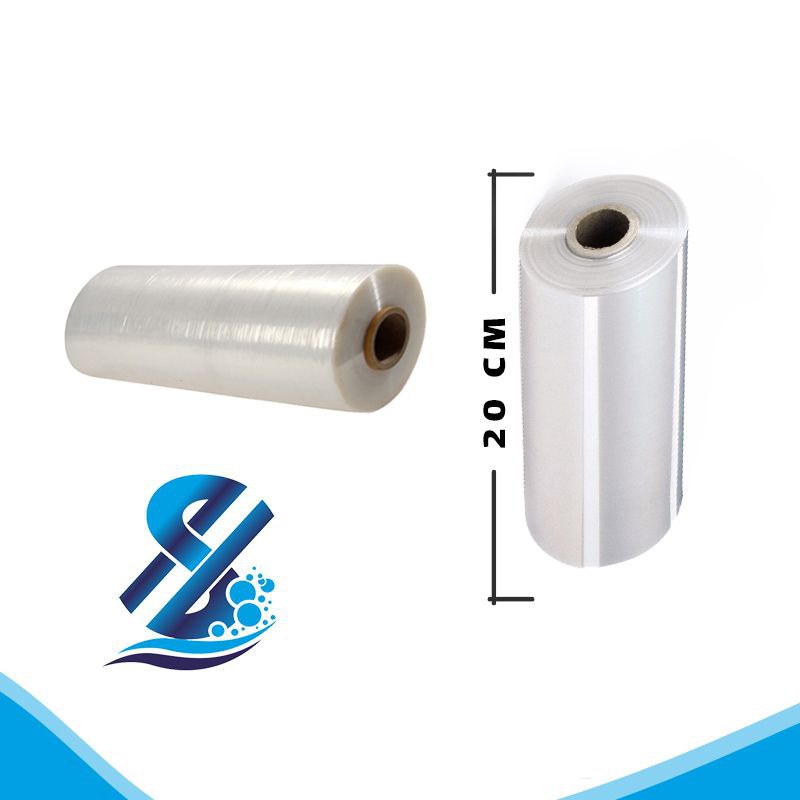

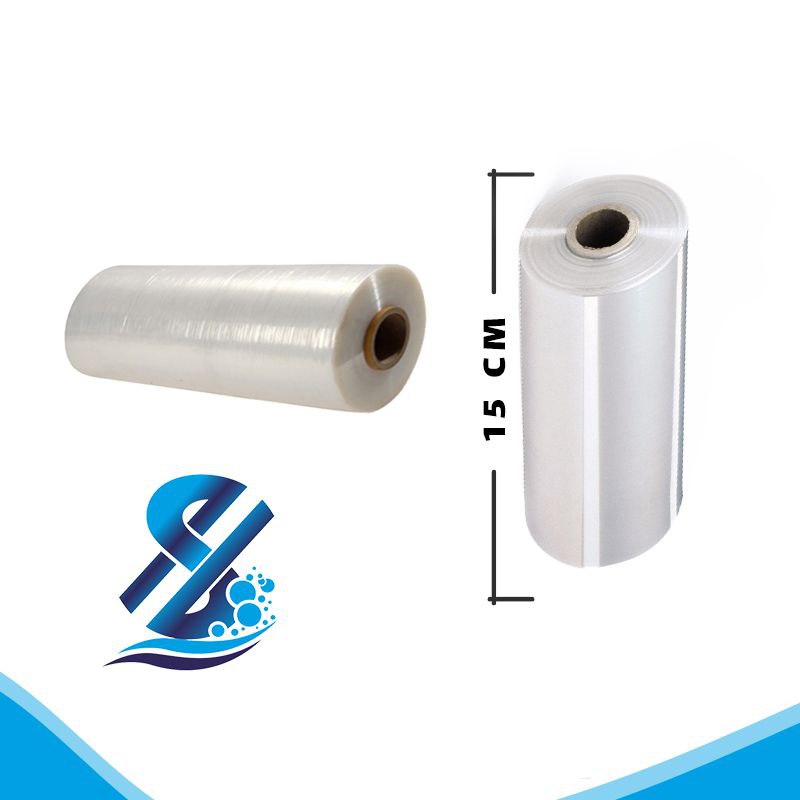

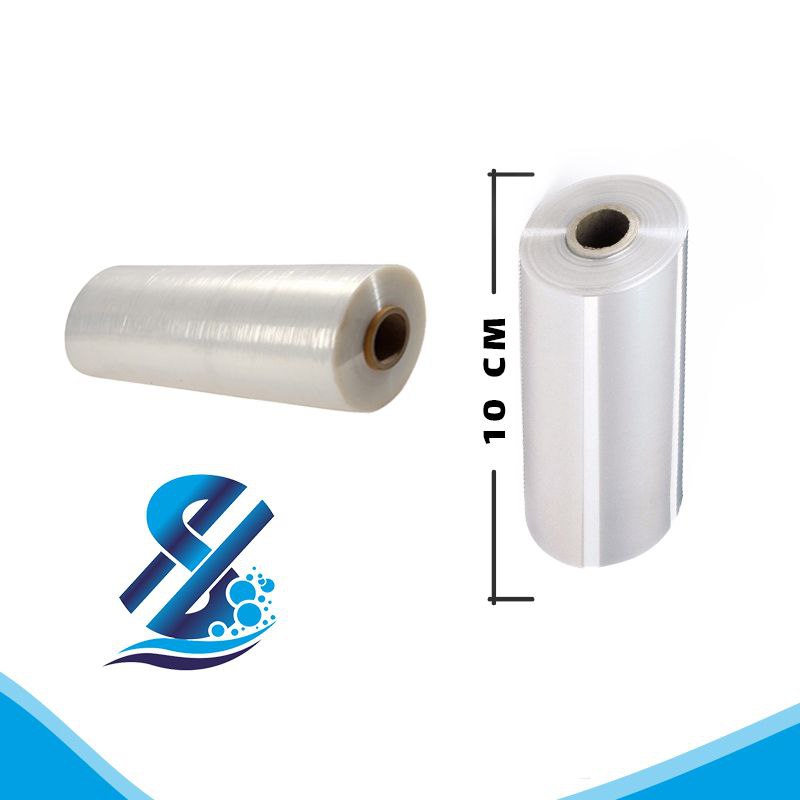

20 cm wrist cellophane, 20 kg bag

- Wrist stretch cellophane with a thickness of 23 microns

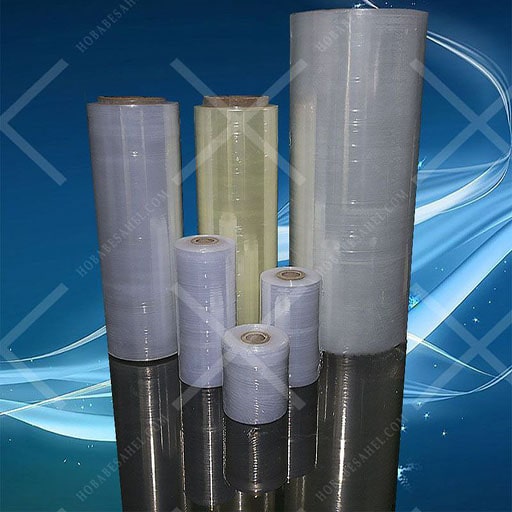

- Available in 10, 15 and 20 cm width.

- Wrist stretch cellophane covers a wide range of applications, for example:

- Carpet and flooring rolls

- Appliances

- Wooden, metal and plastic profiles

- Windows and curtains

- Temporary securing of pallets

- Suitable for all types of online and retail stores

- Versatile packaging with a wide range of applications

- Easier transportation

- Product protection against all external factors and pollution

- Protecting the product against scratches and shocks

Buying high-quality Iranian cellophanes in general and in parts at the best price

Iranian cellophane is considered to be the most widely used material in food and edible packaging. This material is produced from polypropylene and it was first manufactured in France about a hundred years ago. It can be said that no other material can provide us with the capabilities that cellophane has for packaging.

There is no doubt that food packaging should be done very hygienically, and in the meantime, water, moisture, air, sunlight, insects, and dust must be prevented from penetrating food. . Because all these factors can quickly spoil food and destroy the possibility of long-term storage.

Habab Sahel Production is one of the reliable brands producing all kinds of packaging plastics, including cellophane, which has many years of experience in the field of producing these products. The use of high-quality raw materials, advanced production line, up-to-date knowledge and high experience in our collection has finally led to the production of a high-quality final product that has been able to gain the satisfaction of all customers and users.

Getting to know the types of Iranian cellophane

Cellophane itself is divided into different types, each of which is used in different sectors of the industry or in homes. In general, this material can be divided into two main categories: “Teres Cellophane” and “Stretch Cellophane”.

Teres Cellophane

These products do not have adhesive properties and must be connected by thermal sewing machines. Their material is very strong and according to their type of connection, they create a solid and integrated package. This category is also called “wrapping cellophane”. Therefore, if you need a strong packaging and the food must remain fresh for a long time or it is going to travel a long distance to reach its destination, these types of nylons are the best option. This category itself is divided into several other types:

OPP: This type is the thinnest product of this group, but still has high strength and resistance. OPPs are made of polypropylene and appear in the form of a thin plastic sheet.

BOPP: This type is actually an improved form of OPPs. They have more transparency and their strength and thickness are also greater. Also, BOPP has better printability than OPP.

CPP: These products are usually laminated on top of other layers to create a strong package with increased transparency and printability. CPPs also promote the sewability of packaging.

Metallization: As you know, sunlight is one of the factors that causes food to spoil. Therefore, using nylons that prevent sunlight from reaching the food inside the package can be a great option. In metallized cellophane, polypropylene material is combined with aluminum and creates a dark environment inside the package. The most famous example of these products is the plastic used in chips packaging.

Seashell: It has a transparent appearance and is most commonly used in food packaging that needs to be stored in the refrigerator.

Transparent: This category is very thick and therefore has a high protective effect against sunlight. They are used to package materials that must be exposed to customers. A clear example of transparent nylon is pasta packaging.

Stretch cellophane

Stretch nylon has a very good adhesive ability and does not need heat devices to stick. They have high elasticity, which will create a cappier package. This type also has two subcategories.

Food stretcher: These products prevent air and dust from reaching food and allow food to be stored longer. Usually, home packaging of food is done with this type of stretch. An example of food stretch is the packaging of dates and halva.

Industrial stretch: This category is also known as “pallet band”. Industrial stretch is one of the thick nylons and is used for packing large volume products such as furniture.

Advantages of using cellophane

The price of cellophane is lower than other types of nylon packaging, and this has made it an economical option for use in industries. Their appearance is shiny and beautiful and they provide the possibility of a stylish and attractive packaging. Also, they have very good printability and customers can print their name and brand on it.

Due to its higher melting temperature, cellophane is stronger than nylon and nylex. Also, due to its thermal sewing capability, it can be vacuumed and creates a completely sterile and hygienic environment for food.

The width of cellophanes is usually 30 to 40 cm, and their length starts from 2 meters and reaches higher numbers, depending on the user’s needs. The very high flexibility and elasticity of cellophane makes it possible to create food packaging in different ways.