Application of polyethylene foam in different industries

Polyethylene foam is one of the widely used and important materials in various industries, which has become very popular due to its unique features. This material is used in industries such as packaging, automobile manufacturing, and insulation due to its excellent insulating properties, impact resistance, and light weight. Also, polyethylene foam is a suitable choice for various industries due to its compatibility with the environment and its ability to be recycled. In the following, we will examine the use of polyethylene foam in different industries.

What are the uses of polyethylene foam?

Polyethylene foam has wide applications in various industries due to its unique features. In the following, we will examine some of the most important uses of this foam:

insulation

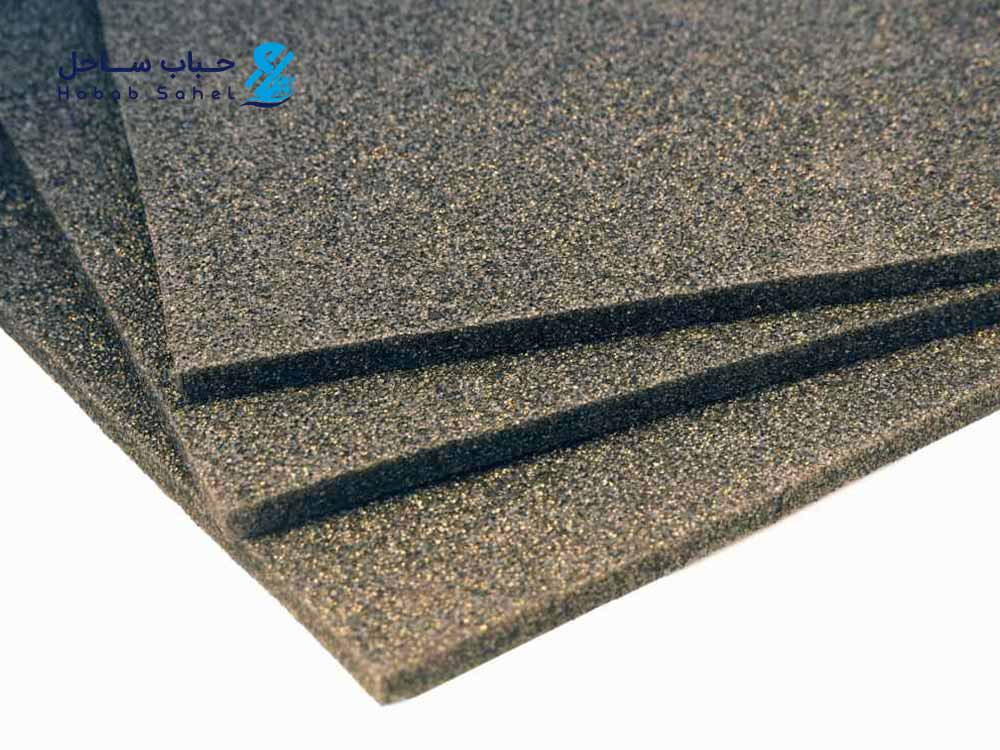

One of the main uses of polyethylene foam is in the construction industry. This foam is used as thermal and sound insulation in walls, floors and ceilings of buildings. For example, polyethylene foam rolls are suitable for insulating large surfaces, such as walls and ceilings, due to their high flexibility, while polyethylene foam board are used for use on floors and areas that require stronger insulation.

Packaging industry

Polyethylene foam is used as an excellent protection for packaging sensitive and fragile products. These foams protect products from physical damage and possible shocks during transportation due to their resistance to impact and pressure. Packaging of electronic products, glass containers and other fragile goods is done well with this foam.

automobile manufacturing

In automotive industry, polyethylene foam is used as sound insulation and vibration reducer. Using this foam in different parts of the car helps to improve the driving quality and reduce the noise inside the cabin.

Sports industries

Polyethylene foam is used in the production of sports mats, flooring and exercise equipment. Due to its softness and shock absorption, this foam guarantees the safety of athletes and prevents possible injuries. Also, polyethylene foam board is used in the production of training boards and underlays.

Water and marine industries

In the marine industry, polyethylene foam is used as insulation in shipbuilding and floating equipment due to its high resistance to water and humidity. Rolled polyethylene foam is also very suitable for insulating water pipes and liquid transportation systems.

The importance of using different types of polyethylene foam in different industries

As mentioned, polyethylene foam plays an important role in various industries due to its special characteristics such as insulation against heat, humidity and sound, as well as being light and flexible. These foams are used in construction to insulate walls and pipes, in packaging to protect sensitive goods, and in the automotive industry to reduce noise and vibration.

The use of roll polyethylene foam and board polyethylene foam helps to improve efficiency, reduce costs, and increase the lifespan of products. These features have made polyethylene foam to find a special place in many industries and to be known as an efficient and effective material.

Advantages of using different types of polyethylene foam

The use of polyethylene foam has many advantages for various industries due to its special features:

Excellent insulation: Polyethylene foam helps to improve energy consumption and reduce costs in buildings as thermal, acoustic and moisture insulation.

Light and portable: The light weight of this foam makes it very easy and inexpensive to transport and install.

Impact resistance: Polyethylene foam protects sensitive products against impact and pressure and is used in packaging.

High flexibility and longevity: Due to its durability and flexibility, this foam is used in various industries, including automotive and sports.

Characteristics of different types of polyethylene foam

Polyethylene foam has unique physical and chemical properties that distinguish it from other materials. These features have made it very useful for use in various industries.

Closed cell structure

Due to its closed cell structure, polyethylene foam has the ability to retain air inside the cells, which increases its insulation power and prevents water and air penetration.

Chemical resistance

This foam is resistant to many chemicals such as acids, bases and oils. This feature makes it suitable for use in industrial environments that deal with chemicals.

Resistant to light and heat

Polyethylene foam has a high resistance to UV rays and thermal changes, and for this reason, it works well in outdoor environments that are exposed to sunlight and different weather conditions.

Variety in thickness and dimensions

Polyethylene foam is produced in various thicknesses and dimensions, and it is possible to cut and mold it in different sizes. This diversity makes it used in many industries including packaging and construction.

Non-toxicity

This foam is also used in food and pharmaceutical industries because it does not release toxic substances and is safe for the environment.

What is the use of polyethylene foam in the packaging industry?

Polyethylene foam is known as an ideal packaging material and is widely used in various industries. One of the prominent features of this foam is its ability to absorb shock and prevent damage to products during transportation.

Insulation

Polyethylene foam is used in insulated packaging to prevent moisture and temperature from penetrating sensitive products. This feature is especially critical for electronic goods and food.

Avoid scratching

By using polyethylene foam, it is possible to prevent scratches and damage to product surfaces. This is especially important for high-value goods such as appliances, furniture and glass.

Compatibility with the environment

Polyethylene foam is known as a recyclable material and thus it is used in environmentally friendly packaging. This feature helps companies to take steps towards sustainability and waste reduction.

Light and flexible

The light weight of polyethylene foam reduces shipping costs and its flexibility allows for special packaging designs. These characteristics have made polyethylene foam a suitable choice for packaging various products.

last word

The use of various types of polyethylene foam in various industries, especially in packaging, shows the importance of this material in the preservation and safety of products. Features such as insulation, scratch prevention and its light weight have made this foam an ideal choice. Polyethylene foams produced by Hobab Sahel protect products well from impact and damage. To take advantage of these benefits, buy from this reliable manufacturer to get the best results in packing and shipping your products.

Production of high quality bubble nylon

What is the best nylon shock absorber for packing?

- +982155246733

- +982155246899

- +989302222003

- +989302222003

- @hobab_sahel

- info@hobabesahel.com

- No. 5, end of the boulevard, Maher Blvd

Maybe these articles will be useful for you.